I want to start off by warning that there’s going to be some circular discussion here (as in heat cycles, thermodynamics, etc.). I’ll try to keep things conceptual in this post, and follow up later with the math underlying the concepts discussed here.

I think everyone understands that getting clothes dry means that we have to evaporate the water that makes them wet. We also know that a typical clothes dryer uses heat to get there, which contains the first piece of thermodynamics we have to wrap our heads around: the water in the clothes must contain sufficient energy (kinetic energy at a molecular level) to overcome the liquid-phase intermolecular forces that hold it in place. Heating is one way to approach that threshold level. The most obvious and immediate example of this is placing an iron on a damp cloth–you almost immediately see steam from the water being evaporated.

Ultimately, we need to reach a particular enthalpy state for the water to become vapor. We can do that by increasing the enthalpy of the liquid water, by decreasing the relative humidity of the environment we’re trying to evaporate into, or a combination of both.

At any given temperature, the amount of energy required to be added to the water to change its state is referred to as either the latent heat of vaporization, or the enthalpy of vaporization.

Your Wet Clothes Make a Swamp Cooler

In a swamp cooler, relatively dry air is passed over a damp surface, evaporating water on that surface and cooling the air. There are several things happening at once:

- A water molecule leaves the surface having drawn energy from the liquid water

- The liquid water has lost energy to the water vapor, and gained energy from the warm air passing over it.

- The air has lost energy to the cooler water

Yes, we’re oversimplifying a bit at this point–we’ll get into some numbers and specifics in a bit. Now think about what happens in a typical (electric for now) clothes dryer:

- Incoming air is heated, with air passing over a damp surface (clothes)

- A water molecule leaves the surface (clothes) having drawn energy from the liquid water

- The liquid water (in your damp clothes) has lost energy to the water vapor, and gained energy from the warm air passing over it.

- The air has lost energy to the cooler water

You probably notice that text being almost a verbatim copy from where I was talking about a swamp cooler, which is where I hope you’ll start to connect the dots between the two physical systems you’re already somewhat familiar with, and things that make them perform better/worse:

- Assuming a fixed runtime, the swamp cooler uses more water (i.e. more evaporation) when you pass more air through it and when the incoming air temperature is higher.

- The clothes dryer gets your clothes drier (English is a wonderful language!) faster when you pass more air through it and when the incoming air temperature (i.e. after the heater) is higher.

- The air entering conditioned space from a swamp cooler and a dryer’s exhaust both contain more moisture than the air going in.

- Humid air going into either one results in less evaporation, and consequently less evaporative cooling.

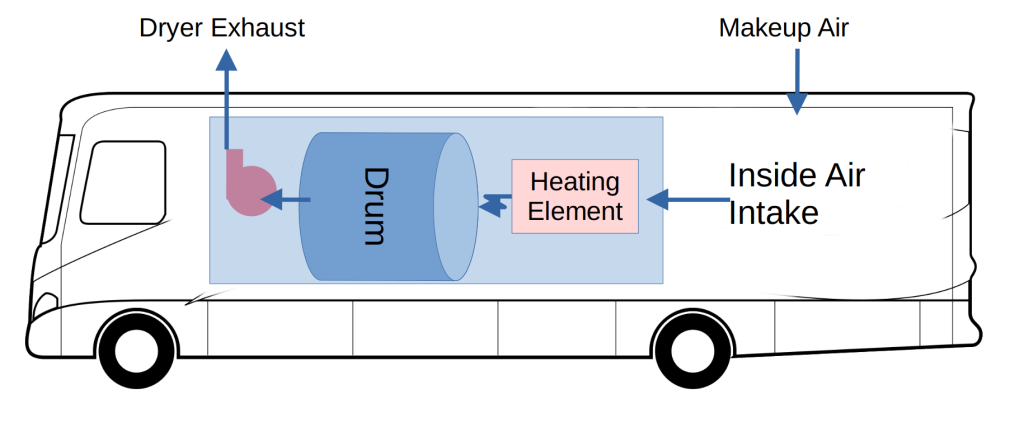

Now let’s step back a little bit. Both of these systems are open-loop swamp coolers, pointed different directions. Take a minute to think about that for a second. A swamp cooler draws in relatively dry, warm air from outdoors, passes it over a damp surface, bringing cooler, more damp air into your living space and pushing conditioned air already in your living space outside. A clothes dryer draws outside air into your living space and heats it. That air then passes over your damp clothes, cooling and moistening the exhaust which goes outside. Pretty similar, right?1 Other than deliberately heating before passing through the wet clothes, the processes are using exactly the same physics. When you run that “air fluff” cycle, you’re using the air inside your RV as the “outside” air trying to cool the outdoors.

If we ignore for a moment the reason we’re running the clothes dryer and just consider what it does for the state of the indoor air, we quickly see that it can be either good or bad, depending on the weather. If it’s cold outside, you’ll obviously have to use a heat source to make up the lost energy of your warm inside air that’s been replaced with cool outside air. But that outside air will be at a lower (perhaps much lower) absolute humidity, drying the air inside. In a typical house, that often means drying the indoor air to more uncomfortable levels, but in an RV can help to prevent condensation on cold outside walls and windows. In warmer weather, you’re bringing in warmer, more humid air–meaning that your air conditioner not only has to cool the replacement air (sensible heat), it also has to condense more moisture to get there (latent heat). In other words, running the dryer in winter weather is generally costing you more in terms of energy use, but can benefit indoor air quality, while in the summer it degrades indoor air quality and increases energy consumption. That’s before we consider the energy the dryer itself consumes heating incoming air and tumbling your clothes, which isn’t exactly nothing.

It should be pretty obvious at this point that if there were a way to dry your clothes in a closed system, your heating and air conditioning needs would be reduced. Condensing dryers like the all-in-one washer dryer systems I talked about last time try to do that. We’ll get to the physics of how that works, but first let’s describe, schematically, how a conventional dryer works:

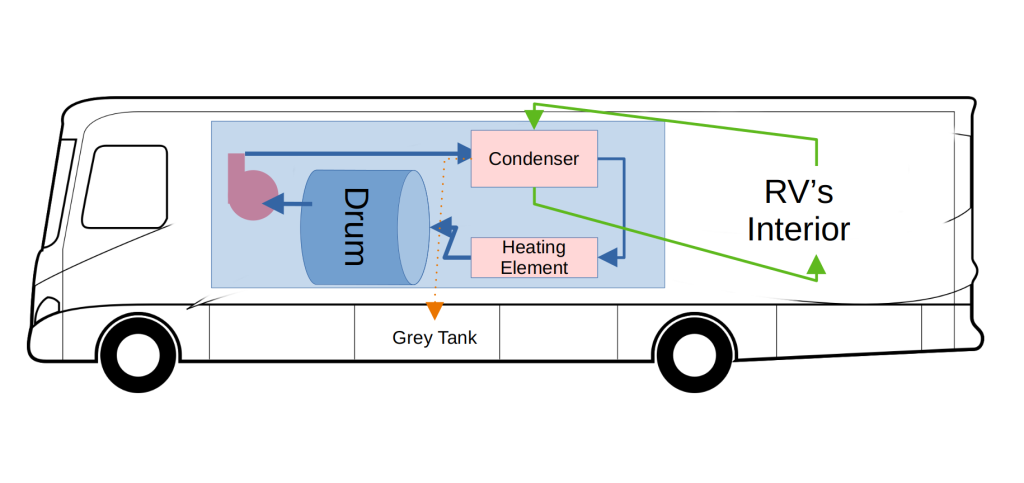

Condensing Dryer Operation

In a condensing dryer, you still have a heating element, but instead of leaving through a vent, air is passed over a heat exchanger and then back across the heating element. That heat exchanger cools the air below the dew point, causing condensation. This water is either collected in a tank or drained via a small line. So we heat the air, lowering its relative humidity, pass it over damp clothes taking on water vapor and cooling it, cool it further to condense moisture, then heat it up again. No moisture leaves the dryer except in liquid form.

How does the cooling work? In a typical condensing dryer (i.e. one with heating elements and without a water supply), the other side of that heat exchanger is just room air passing over it. This effectively means that you have to get the dryer hot enough that it can take on enough moisture for the dew point to exceed room temperature, plus the difference in temperature across the air-to-air heat exchanger.

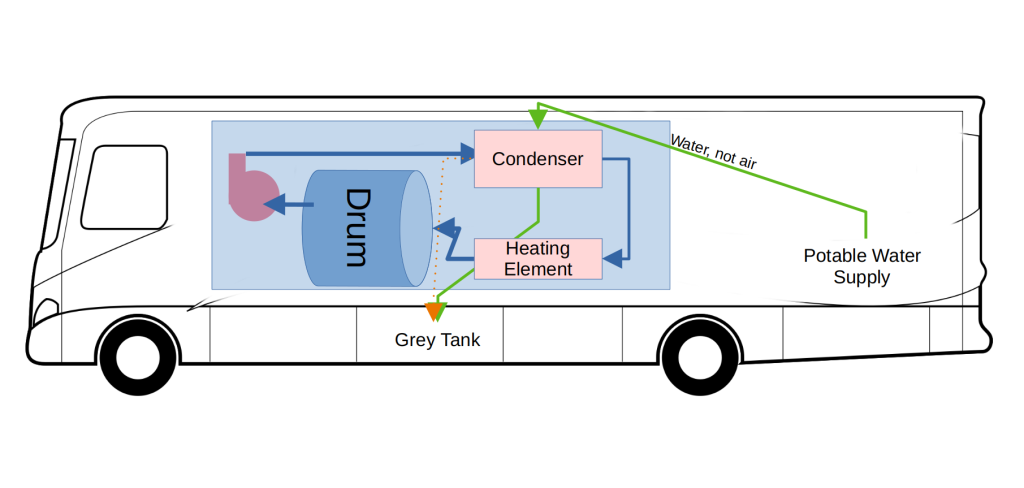

An astute reader will now be wondering if there’s a way to get that heat exchanger colder, and the first step in that direction is a condensing dryer that uses a water supply on the cold side of the heat exchanger, as is common in condensing dryers for RVs. With a small interior volume, exhausting all the heat from drying into your RV wouldn’t stand a chance in the summer! Using water also means that the heat exchanger can be more compact, and/or the heating elements lower power for the same drying time–an air-to-water heat exchanger of the same size will have a lower temperature differential.

But we’re still limited by the temperature of the water on the low end, and that temperature plus the energy added by the heating elements on the high end. Can we do better? Of course!

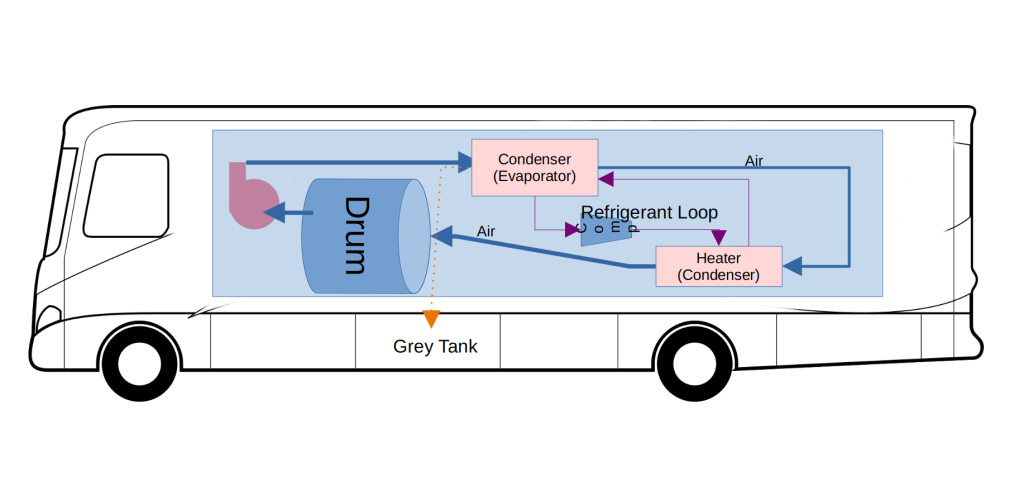

Heat Pump Dryer Operation

I could probably write a small book on the physics of heat pump operation, but for now let’s leave it at this simple description: a heat pump circulates a refrigerant to absorb heat in one location and reject it in another. Your air conditioner works by taking on heat in one location (i.e. the room) and rejecting it in another (outside). Your refrigerator takes heat from one location (where you keep the beer) and rejects it in another (where you keep the potato chips).

In both of those systems, we may also have condensation (i.e. drying) in the part of the system we’re cooling, depending on the conditions inside, but we deal with them in different ways. The air conditioner generally dumps the water outside somewhere (an RV air conditioner typically just drains onto the RV’s roof) or uses a small pump to get rid of it. The refrigerator generally drains to the back of the cabinet, evaporating the water outside (or in your kitchen) by passing the compressor discharge line through it.

A heat pump dryer is somewhat similar, but because we’re interested in the drying more than the heat transport, we can operate it ever so slightly differently. The heat pump heats air by passing it over a warm condenser coil, with that slightly warmer air going into the drum and helping to evaporate water from the clothes inside. The slightly more humid air then passes over the cool evaporator coil, dropping the air temperature below the dew point and condensing water from the air. The cooler, drier air then closes the loop, passing over the warm condenser coil and back into the drum.

To this point in the description, what’s going on with the air flowing in a closed loop inside the dryer isn’t conceptually any different from the condensing dryers we’ve already discussed. But in terms of how it interacts with its surroundings, the two couldn’t be further apart. Recall that the condensing dryer uses a heating element on the hot side, and room air or water on the cold side. Now notice that the heat pump dryer doesn’t have an inlet or exhaust for room air–the energy removed from the cold side is transported via refrigerant and goes back into heating the hot side.

Note that there’s no heat source, per se. The only heat added is a result of the heat pump’s compressor doing work moving the refrigerant around. Obviously, the compressor does consume energy, but it’s much less–comparing a few models offered overseas (where clothes dryers get a standardized energy consumption metric), a conventional vented dryer uses about three times more energy than its equivalent heat pump model under standardized testing conditions. A conventional condensing dryer is slightly more efficient than a vented dryer, by maybe 10% or so.

Of course, that’s not the whole story. Not even close:

- The drying performance of both conventional dryer types will depend significantly on ambient conditions.

- The three dryer types have varying impacts on our RV’s inside atmosphere–either helping or hurting depending on the weather.

- We also care about how long it takes, and power consumption during the cycle